SPC (Stone Plastic Core Layer) Flooring

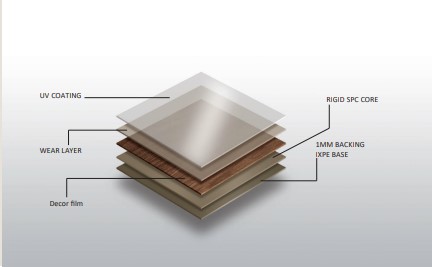

1. UV Resistant Layer

The UV-resistant layer (UV protection layer) is the coating applied on the top layer of the SPC flooring. This coating blocks ultraviolet rays and protects the surface by resisting ultraviolet rays and preventing further penetration of ultraviolet rays, thereby maintaining the strength and color of the materials below the coating. and appearance. The UV layer is also waterproof and dirt-proof.

2. Wear Layer

The Wear Layer or Abrasion layer is a clear coating that provides protection against floor abrasion, this coating is waterproof, stain and scratch resistant, embossed to provide texture to the floor. The thickness of the wear-resistant layer plays a crucial role in the lifespan of the SPC floor, and its thickness distinguishes the floor for different uses such as heavy commercial, light commercial and residential. It is the perfect protection for the pattern color of the decorative layer below.

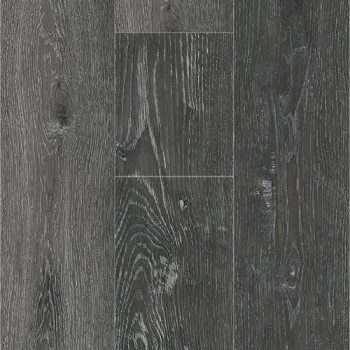

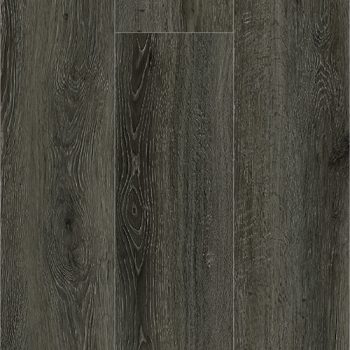

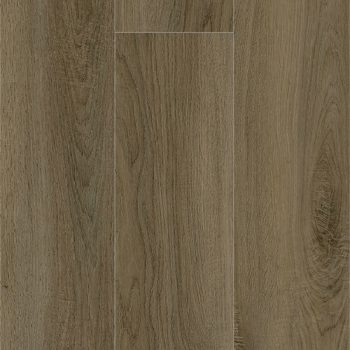

3. Decorative Film Layer

Decorative Film Layer, also known as Color Film Layer, is a thin PVC film for printing decorative layers of different color patterns. This printed color film defines the look of the floor and is printed in a variety of colors, patterns and textures. In the SPC floor market, the most common pattern is natural wood grain. With the development of printing technology, the printed pattern has a high degree of realistic look, and it is almost difficult for the naked eye to distinguish whether it is a printed pattern or a real wood block. In addition to wood grain, marble-patterned SPC stone-plastic flooring is also becoming popular.

4. Core Layer

The Core Layer is the thickest and hardest layer, and it is the most important structural layer of SPC stone-plastic floor (Stone and Polymer/Plastics composite): made of limestone, polyethylene (polyvinyl), these substances combine to provide a high density, extremely stable and waterproof material. The stone-plastic compound prevents expansion and contraction caused by temperature and humidity, keeping the floor in good condition and durable for a long time. The locking system of this core substrate layer makes the SPC flooring planks seamlessly locked firmly together, and the installation can be completed without any glue. In general, SPC floors with thicker substrate layers provide greater stability and underfoot comfort.

5. Underlayment

Underlayment, also known as mute layer (as the name suggests, is the bottom layer of SPC floor mats, usually made of cork, EVA or IXPE. Most SPC stone plastic floor brands have pre-assembled backing cushions and the thickness is generally 1.0mm or 1.5mm. The cushion layer has the effects of buffering, shock absorption, water resistance and sound absorption. These bottom-layered cushions stabilize the SPC floor, support it, and increase the softness of the SPC Core Vinyl Flooring, thereby improving the comfort of the foot. This mute layer can absorb more sound, shock and provide cushioning effect, reducing the noise and vibration of the room when walking. EVA or IXPE cushions are both waterproof and moisture-proof, but IXPE underlayment layer belongs to polymer environmental protection material. In comparison, IXPE has better sound insulation, shock resistance and cushioning effect than EVA mute pads. IXPE is more durable, more environmentally friendly, and provides a more comfortable and softer foot feel.

SPC Flooring Brand Structure

- UV Resistant Layer - Block Ultraviolet Rays

- 0.55mm (22mil) Wear Layer - For High Durability

- Decorative Film Layer) - High-quality 3D Printing

- 1.5mm IXPE Underlayment - Better Sound Insulation, Shock Resistance and Cushioning Effect